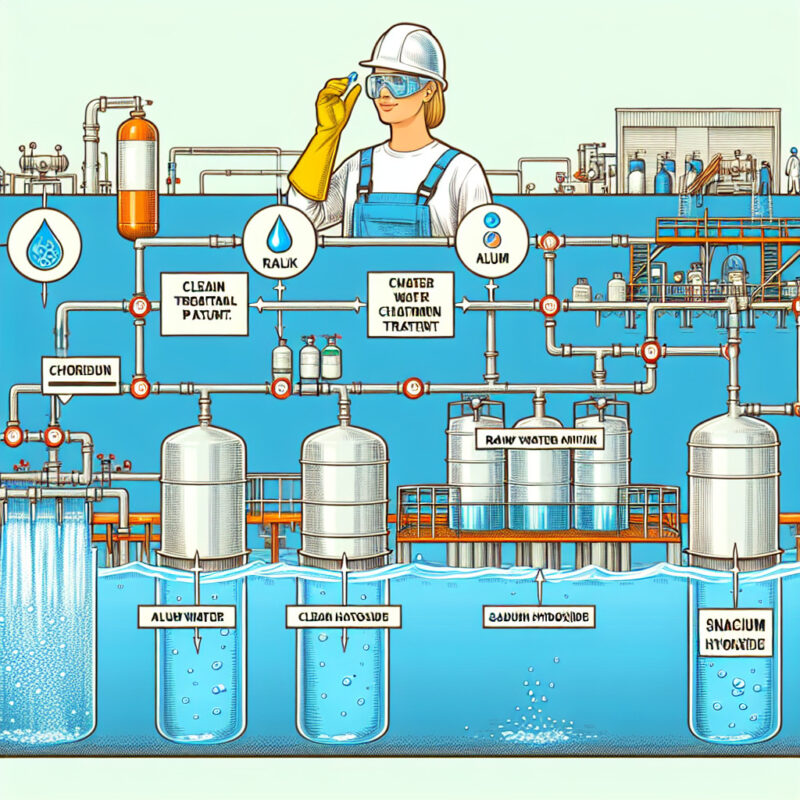

Water treatment plants play a crucial role in keeping our drinking water safe, clean, and free from harmful substances. To accomplish this, these treatment plants employ a variety of chemicals in their processes. These chemicals are carefully selected and used in specific quantities to effectively remove impurities, kill bacteria and viruses, and improve the overall quality of the water we consume. Understanding what chemicals water treatment plants use is vital for appreciating the extensive efforts put forth to ensure the provision of clean and potable water to communities worldwide.

key Takeaways

- Water treatment plants rely on chemicals to remove impurities and make water safe for consumption.

- Coagulants, such as aluminum sulfate or ferric chloride, are used to clump together fine particles in the water, making it easier to remove them.

- Disinfectants, like chlorine or UV radiation, are essential for killing harmful bacteria and viruses in the water.

- pH adjustment chemicals, such as lime or soda ash, are used to regulate the acidity or alkalinity of the water.

- Corrosion inhibitors, such as orthophosphates, are added to prevent pipelines and plumbing from deteriorating.

- Controlled amounts of fluoride are often added to prevent tooth decay.

- Water treatment plants produce sludge, a byproduct that requires proper disposal or treatment.

- It is important for water treatment plants to follow regulatory standards and continuously monitor the water quality.

- Water treatment technologies are evolving to address emerging contaminants, such as pharmaceuticals or microplastics.

The Chemicals Used in Water Treatment Plants

Water treatment plants play a crucial role in ensuring the safety and cleanliness of our drinking water. These facilities utilize a variety of chemicals to remove contaminants and purify the water before it reaches our taps. In this article, we will explore the various chemicals used in water treatment plants and their specific functions.

Coagulants

Coagulants are chemicals used to destabilize suspended particles and facilitate their clumping together, making them easier to remove during the sedimentation and filtration processes. Common coagulants used in water treatment plants include aluminum sulfate (alum) and ferric chloride. These chemicals neutralize the negative charge on the particles, causing them to come together and form larger solids called flocs.

Flocculants

Flocculants are polymers that are added to the water after the coagulation process. They help the flocs to agglomerate and settle more quickly. Flocculants improve the efficiency of the sedimentation process and aid in the removal of smaller suspended particles that may have escaped coagulation. Polyacrylamide is one of the commonly used flocculants in water treatment plants.

pH Adjusters

pH adjusters are chemicals used to regulate the acidity or alkalinity of the water. The proper pH level is important for effective coagulation and disinfection. Lime (calcium hydroxide) and soda ash (sodium carbonate) are commonly used as pH adjusters in water treatment plants. They raise the pH of acidic water to the desired range, allowing other treatment processes to occur effectively.

Disinfectants

Disinfectants are crucial in eliminating harmful microorganisms from the water supply. Chlorine is the most commonly used disinfectant in water treatment plants, in the form of either chlorine gas or sodium hypochlorite. These chemicals effectively kill or neutralize viruses, bacteria, and other pathogens, ensuring the safety of the treated water.

Corrosion Inhibitors

Corrosion inhibitors are chemicals that are added to prevent the deterioration of pipes and plumbing infrastructure. Water treatment plants often add inhibitors, such as orthophosphates or silicates, to create a protective coating on the inside of the pipes, preventing them from corroding or leaching harmful substances into the water.

Conclusion

Water treatment plants rely on a combination of chemicals to purify our drinking water. Coagulants and flocculants aid in the removal of suspended particles, pH adjusters ensure optimal conditions for treatment, disinfectants eliminate harmful microorganisms, and corrosion inhibitors protect the infrastructure. By understanding the role of these chemicals, we can appreciate the efforts made to deliver clean and safe drinking water to our homes.

Frequently Asked Questions

What are the main chemicals used in water treatment plants?

Water treatment plants commonly use chemicals such as chlorine, aluminum sulfate, polyaluminum chloride, and lime. These chemicals play a crucial role in removing impurities and pathogens from the water, ensuring its safety for consumption.

Why is chlorine used in water treatment?

Chlorine is used in water treatment plants because of its disinfectant properties. It is highly effective in killing bacteria, viruses, and other harmful microorganisms that may be present in the water. By adding chlorine to the water, the risk of waterborne diseases is significantly reduced, making it safe to drink and use.

Are the chemicals used in water treatment safe?

Yes, the chemicals used in water treatment plants are carefully regulated and dosed to ensure their safety. The levels of chemicals, including chlorine, are closely monitored to maintain drinking water standards and to protect public health. Extensive research and testing have been conducted to determine the appropriate concentrations of these chemicals for effective treatment without posing any adverse effects on human health.

Are there any alternatives to chlorine for water disinfection?

Yes, there are alternative disinfection methods to chlorine, such as ultraviolet (UV) disinfection and ozonation. UV disinfection uses UV light to destroy microorganisms, while ozonation involves the use of ozone gas. These methods can be effective in killing pathogens and reducing the need for chlorine disinfection. However, it’s important to note that each method has its own advantages, limitations, and cost considerations, which should be carefully evaluated before implementation.

How are the chemicals removed from the water after treatment?

After the water has been treated with chemicals, various processes, including filtration, coagulation, and settling, are used to remove the chemicals and any remaining impurities. Filtration involves passing the water through layers of sand or other media to remove particles, while coagulation encourages the particles and chemicals to come together and settle. These processes ensure that the water supplied to consumers meets the required quality standards and is free from residual chemicals.

Options for Water Treatment: Pros and Cons

Ultraviolet (UV) Disinfection

UV disinfection is a chemical-free and eco-friendly option for water treatment. It works by exposing the water to UV light, which destroys bacteria, viruses, and other microorganisms. One of the main advantages of UV disinfection is that it does not produce harmful byproducts or alter the taste of water. However, it is unable to remove certain chemicals or particles and may require additional treatment steps to ensure comprehensive purification.

Reverse Osmosis (RO)

Reverse osmosis is a highly effective method for removing impurities from water. It involves forcing water through a semipermeable membrane, which filters out dissolved solids, contaminants, and microorganisms. RO systems can remove a wide range of chemicals, including heavy metals and salts. However, it is an energy-intensive process and has a relatively slow filtration rate, requiring additional equipment and maintenance.

Final Thoughts on What Chemicals Do Water Treatment Plants Use

In conclusion, water treatment plants use a combination of chemicals to ensure the safety and cleanliness of the water supply. Chlorine remains one of the most commonly used chemicals for disinfection due to its effectiveness in killing bacteria and viruses. However, alternative methods like UV disinfection and ozonation are gaining popularity as eco-friendly options with specific advantages and limitations. Regardless of the method chosen, it is important to carefully monitor and regulate the chemical levels to ensure they meet the required standards and do not pose any health risks. Overall, the goal of water treatment plants is to provide clean and safe drinking water to the public by utilizing appropriate chemicals and treatment processes.

It is crucial to understand and appreciate the efforts put into maintaining high water quality standards by water treatment plants and the continuous improvements in the field. The selection of chemicals and treatment methods requires thorough research, evaluation of local conditions, and adherence to regulatory guidelines. By continually exploring alternative disinfection options and optimizing existing processes, water treatment plants can enhance the efficiency and sustainability of water treatment, ensuring the availability of clean and safe water for everyone.